NANO FELEZ:

Experience is the most honest educator, and everything it teaches is beneficial.

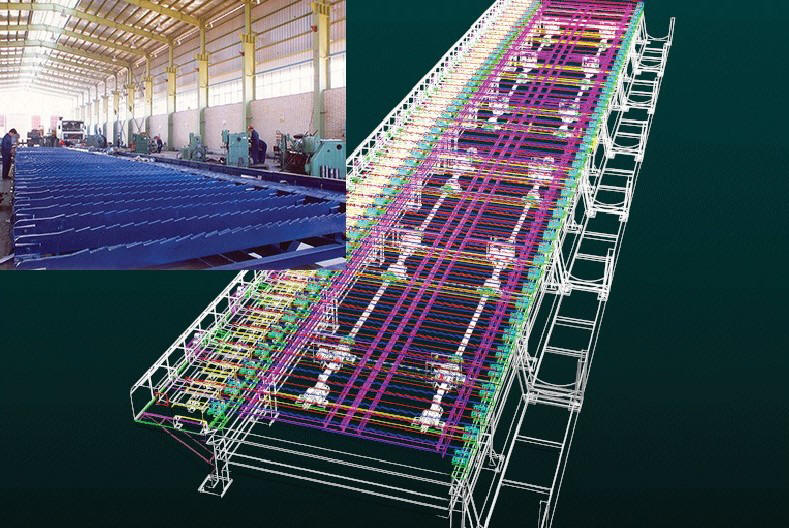

It has been successfully designed, manufactured, and installed a cooling table for rolled steel products with dimensions L14000 × W2300 × H850 mm.

The system is engineered to guide and control 40 mm angle profiles with lengths up to 12000 mm, and it is capable of cooling and preparing up to 30 tons of products per day, depending on size and specifications.

By optimizing the table’s motion technology and eliminating the hydraulic system, this solution stands unrivaled in the rolling industry—delivering higher efficiency, reduced maintenance costs, and improved value chain.

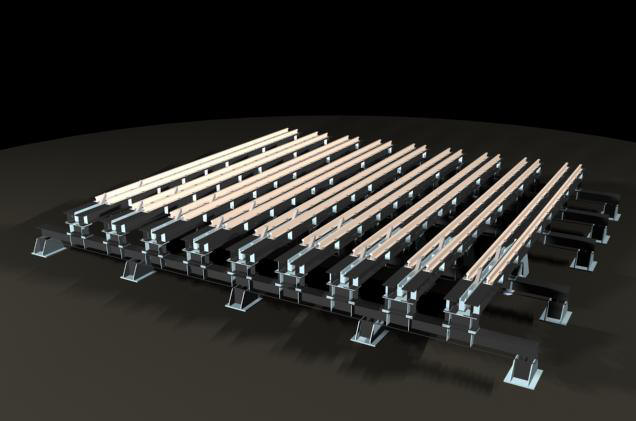

NANO FELEZ - Walking Beam Cooling System for Steel Billets

Nanofelez has designed a walking beam cooling system for steel billets, providing an efficient solution to enhance precision and metallurgical quality in the rolling process.

This project was accomplished by applying advanced engineering expertise, technical knowledge, and production line data. The use of high-quality materials combined with modern cooling technologies ensures durability, reliability, and optimal performance.

This achievement reflects Nanofelez’s commitment to innovation and excellence in serving the steel industry.

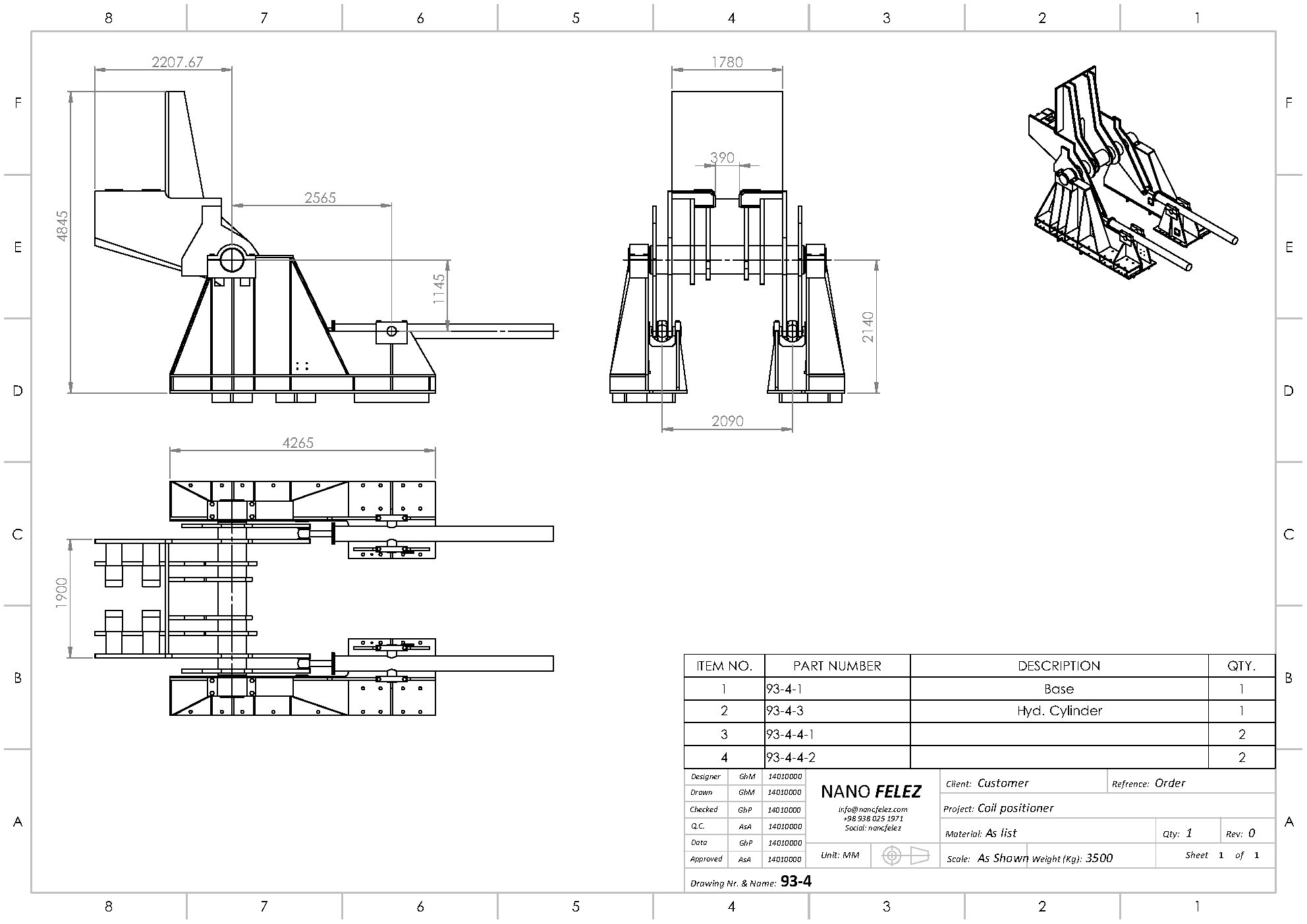

Detail engineering and force analysis of sheet coil direction

changer for easy transportation

by L-shaped hook in steel factories

Analysis with engineering software in reducing and optimizing

material consumption and calculating the force of the hydraulic

jack adds to the quality of work and its implementation

guarantee.

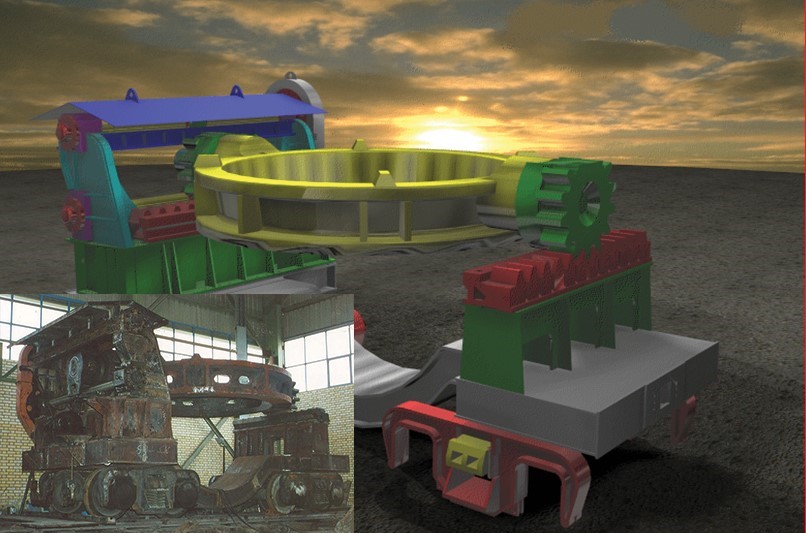

Nanofelez has engineered the detailed design and construction of the hot blast ring surrounding the blast furnace, providing a reliable solution for the uniform injection of hot air into the furnace.

Precision in engineering and design ensures the quality of construction, making this component a vital element in enhancing efficiency and stability within the smelting process.

Through reverse engineering, Nanofelez has successfully designed and manufactured a slag carrier wagon based on limited drawings and worn-out components. This large-scale wagon operates on rails and is pulled in a uniform train chain by a locomotive. Each wagon is equipped with the ability to rotate the ladle and discharge materials efficiently. This project stands as a distinguished example of Nanofelez’s expertise in redesigning heavy industrial equipment and delivering reliable solutions for the steel and metallurgical industries.

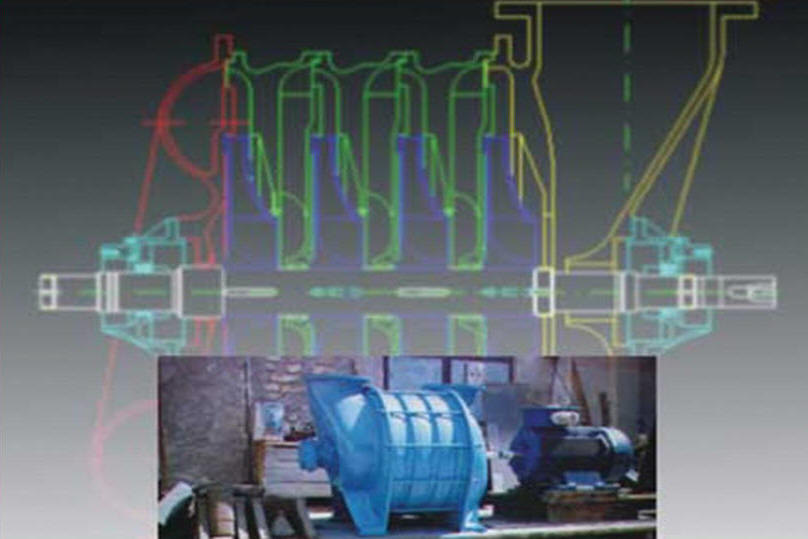

Through reverse engineering, Nanofelez has successfully designed and manufactured a four-stage air fan with approximate dimensions of 2000 × 1500 × 1500 mm.

The system ensures a stable airflow and consistent production speed, with identical performance across all four stages and no dimensional variations.

Its modular design allows for additional or fewer stages to be applied, providing exceptional flexibility and making this fan a reliable and efficient solution for diverse industrial applications.

All right reserved.

NANO FELEZ

NANO FELEZ PARSA Co.

Register Nr. 71838, National ID Nr. 14011425174

Address: 2nd floor, Nr. 200, Vahid St., Isfahan, IRAN

Postal Code: 81 75 94 54 87

Tel.: +98 (31) 3627 9540

Contact information:

Company Cell phone: +98 938 025 1971

E-mail: info@nanofelez.com

Social Network: NANOFELEZ

And many other experiences, Contact us.